Zida zapakhomo za PCB

AKE PCB imapereka zida zingapo zosankhidwa kuphatikiza Bukuli, Semi-Zosindikiza Zowonjezera, Zosankha & Makina A Bnchtop Ndipo Kutsika kwa Pakatikati Pazisonkhanizi

Ku Anke PCB timamvetsetsa bwino ndiye cholinga chachikulu cha msonkhano wa PCB ndipo timatha kukwaniritsa malo omwe ali ndi luso lapamwamba lomwe likutsatira zopanga zaposachedwa kwambiri za PCB.

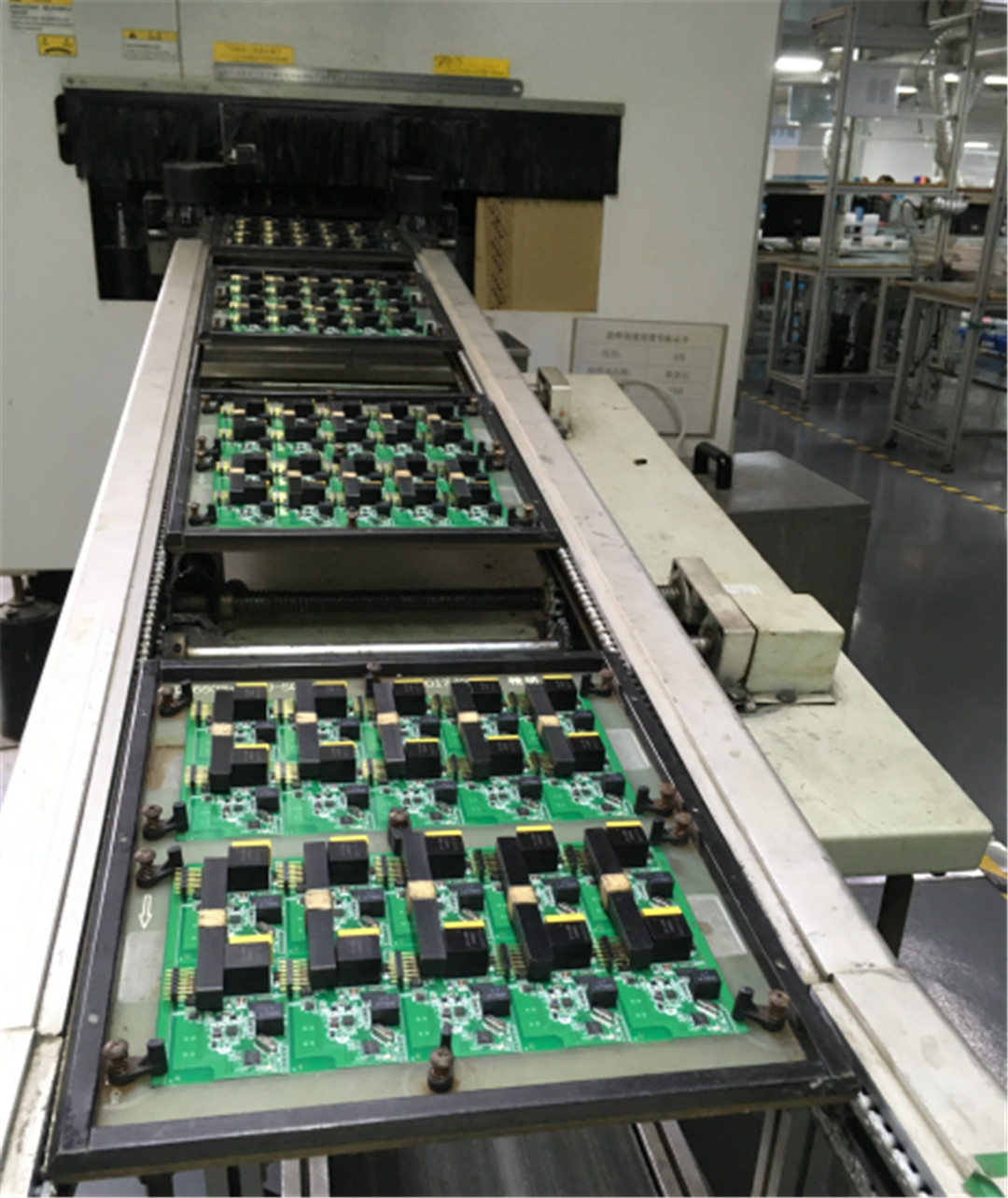

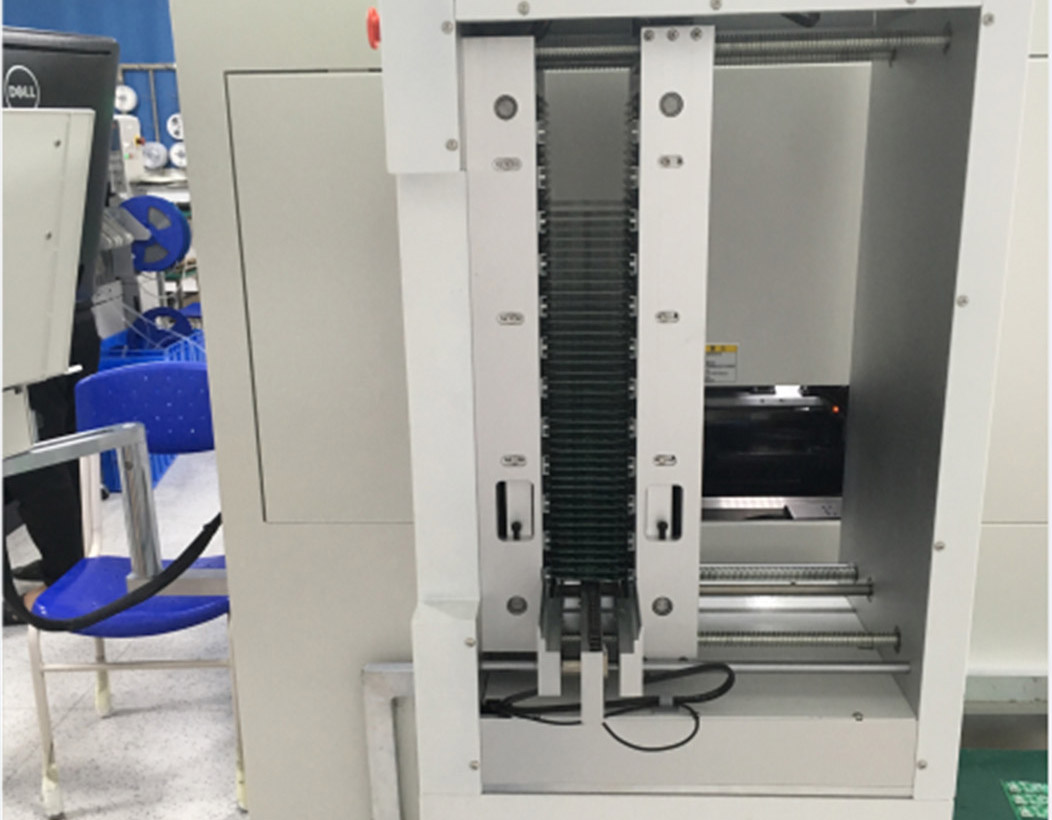

Ogwira PCB Yonyamula

Makinawa amalola mabodi a PCB kuti adyetse mu starting starder makina osindikiza.

Mwai

• kupulumutsa nthawi kuti agwire ntchito

• Mtengo wopulumutsa pamsonkhano

• Kuchepetsa cholakwika chomwe chingachitike

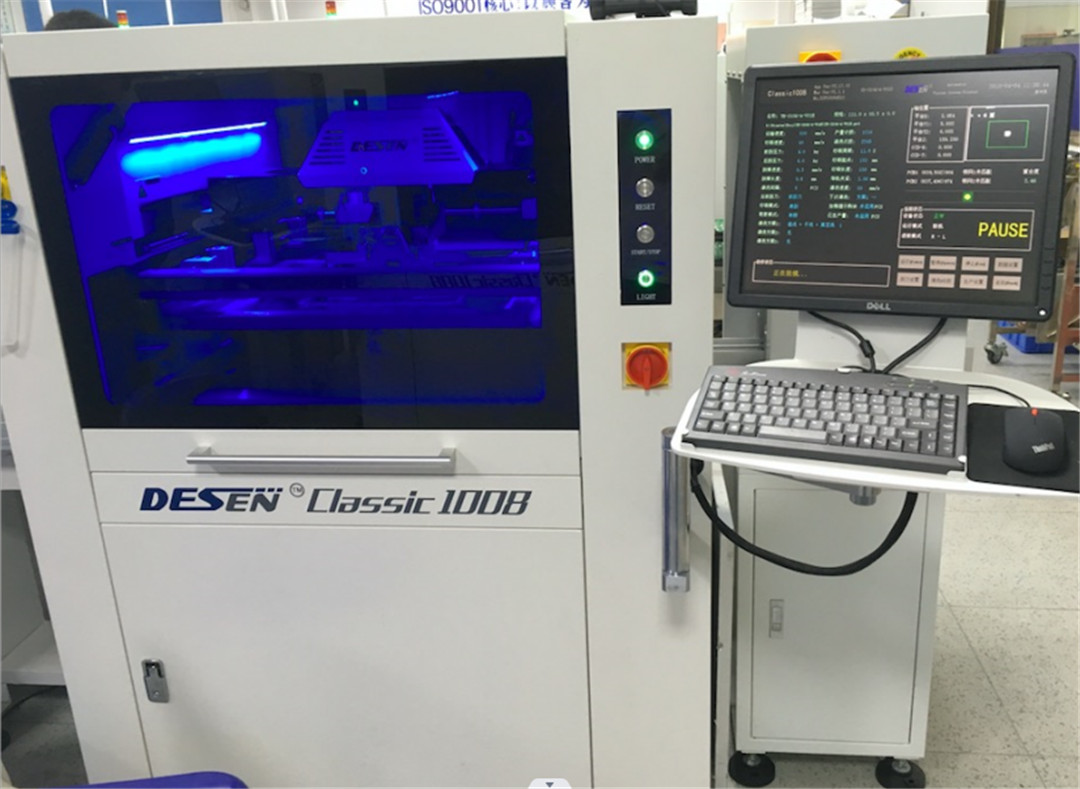

Chosindikizira chosindikizira chokha

Nyengo ili ndi zida zapamwamba monga makina osindikizira okha.

• Pulogalamu

• Phula

• Zosankhidwa zokha

• Njira yoyeretsa yokha

• Kusamutsa kwa PCB ndi dongosolo

• Kusavuta kugwiritsira ntchito mawonekedwe achingerezi / Chitchaina

• Dongosolo la zithunzi

• Kuyendera 2d & Spc

• kuphatikizika kwa CCD

SMT Sankhani & Malo Makina

• Kulondola kwambiri ndi kusinthasintha kwa 01005, 0201, Soic, PLGA, MBGA, QFP, qfp, mpaka 0.3mm

• Kusagwirizana ndi malo ogwirizana ndi olemba kuti musangalale kwambiri komanso kukhazikika

• Makina anzeru a Florement amapereka mawonekedwe operekera zakudya, kuphatikiza gawo la mapangidwe, kusinthika kwa data

• Makina a Cognex Amisala "masomphenya pa ntchentche"

• Pansi panjira yolumikizidwa ndi qfp & bga

• Zoyenera kupanga zazing'ono & zapakatikati

• Makina opangidwa ndi kamera omwe ali ndi Smain Science Puthinc

• Dongosolo lanyumba

• Kuyendera masomphenya musanapange

• Kutembenuka kwa anthu wamba

• Vuto la Kuyika: 10,500 CPH (IPC 9850)

• Makina a mpira mu x- ndi y-nkhwangwa

• Oyenera ma tepi anzeru 160 anzeru

Makina owongolera otsogola / otsogola

• Mapulogalamu a Windows XP Operation ndi njira zina zachi China komanso Chingerezi. Dongosolo lonse pansi

Kuyang'anira kuphatikiza kwake kumatha kusanthula ndikuwonetsa kulephera. Zambiri zonse zopanga zitha kupulumutsidwa kwathunthu ndikusanthula.

• PC & SIEMENES PLC KUGWIRA NTCHITO YOPHUNZITSIRA; Kulondola kwambiri kubwereza mbiri kungapewe kutaya zinthu zomwe zimachitika pakuyendetsa kompyuta.

• Mapangidwe apadera a kumangidwa kwa mafuta a madera otenthetsera anayi kuchokera mbali 4 amapereka mphamvu kwambiri; Kusiyana kwa kutentha kwambiri pakati pa magawo awiri ophatikizika kungapewe kusokonekera kutentha kutentha; Itha kufupikitsa kutentha kwa kutentha pakati pa zigawo zazikulu ndi zazing'ono ndikukwaniritsa thandizo la PCB yovuta.

• Kukakamiza mpweya wozizira kapena madzi ozizira ozizira ndi kuthamanga kwabwino kumayenera mitundu yonse yoyeserera kwaulere.

• Kugwiritsa ntchito mphamvu zochepa (8-10 kwh / ola) kuti musunge mtengo wopanga.

AOI (makina oyendetsa makina oyendetsa)

AOI ndi chida chomwe chimazindikira zoperewera pakuwuma potengera mfundo zowona. AOL ndiukadaulo woyeserera wosiyidwa, koma zikukula mwachangu, ndipo ambiri opanga akhazikitsa zida zoyesera a al.

Pa nthawi yoyendera, makinawo amangoyendetsa PCBA kudutsa kamera, amasonkhanitsa zithunzi, ndikufanizira mbali yolumikizidwa ndi magawo oyenerera omwe ali ndi magawo oyenerera. Kukonza kukonza.

Tekinolo yothamanga kwambiri, yamalingaliro oyenda bwino kwambiri imagwiritsidwa ntchito polemba zolakwitsa zokhudzana ndi malo olakwika ndi zilema za mab.

Mabodi a PC amasiyanasiyana kuchokera kumabodi okwera kwambiri mpaka ma board otsika kwambiri mpaka matabwa akuluakulu akuluakulu, ndikupeputsa njira zopezera pa intaneti kuti zithandizire kupanga bwino.

Pogwiritsa ntchito AOL ngati chida chotsika chakuchepetsa, zolakwika zimatha kupezeka mwachangu pamsonkhanowu, zomwe zimapangitsa kuwongolera bwino. Zofooka zoyambirira zimalepheretsa matabwa olakwika kuti asatumizidwe kumisonkhano yotsatirayi. AI adzachepetsa mtengo wokonza ndipo pewani matabwa osenda osakonzekera.

3d x-ray

Ndi chitukuko chachangu cha ukadaulo wamagetsi, miniaturization ya msonkhano waukulu, wopitilira kamtunda wa matekiti osiyanasiyana, zofuna za msonkhano wadera ladera likukwera kwambiri.

Chifukwa chake, zofunika kwambiri zimayikidwa njira ndi matekinoloje.

Kuti tikwaniritse izi, maluso atsopano amasuta nthawi zonse, ndipo ma X-ray oyang'anira X-ray amayang'ana ukadaulo wa X-Ray ndi woimira.

Sizingazindikire mafupa osawoneka, monga BGA (mpira gid gray, phukusi la mpira), etc., komanso kusanthula koyenera ndi zotsatira za zojambulazo kuti mupeze zolakwa.

Pakadali pano, njira zingapo zoyeserera zimagwiritsidwa ntchito poyeserera msonkhano wamagetsi.

Zida zofananira ndizowunikira zolemba zamagulu (MVI), ku Dester Tyerter (ICT), ndi zowoneka zokha

Kuyendera (kuyendera kokha). AI), kuwunikira kwa X-ray (axi), ma tepi ogwiritsira ntchito (ft) etc.

PCAVATE HORK

Ponena za kusintha kwa msonkhano wonse wa SMT kuli ndi zinthu zingapo monga kutetezedwa, kuwongolera, kukhazikitsidwa, kuyika, ndikuyeretsa, kuyika, ndi kuyeretsa.

1. Kusaka: Njira iyi ndikuchotsa zigawo zokonzedwa kuchokera ku PB ya zigawo za SMT. Mfundo yofunika kwambiri siyikuwononga kapena kuwononga zigawo zomwezo, zigawo zozungulira ndi mapepala a PCB.

2. Kupukusa kwa compict: Pambuyo pa kusintha kwa magawo kumakonzedwa, ngati mukufuna kupitiliza kugwiritsa ntchito zigawo zochotsa, muyenera kukonza zigawozo.

3. Kuyeretsa padb: Kuyeretsa PCB Pad kumaphatikizapo kukonza madambo. Kutsitsa kwa Pad nthawi zambiri kumatanthauza kukhazikitsa kwa PCB Pad Pad wa chipangizocho. Kuyeretsa nthawi zambiri kumagwiritsa ntchito wogula. Chida chotsuka, monga chitsulo choyenera, chimachotsa msirikali wochokera pa ma pads, kenako ndikupukuta ndi mowa wotheratu kapena zoyeserera zovomerezeka kuti muchotse ziphuphu ndi zotsalira zotsalira.

4. Kuyika kwa zigawo: Onani PCB yosinthidwa ndi ogulitsa osindikizidwa; Gwiritsani ntchito chipangizo chophatikizira cha maofesi owonjezera kuti musankhe phokoso loyenera ndikukonzanso PCB kuti iyikidwe.

5. Ntchito: Ntchito yogulitsa ndalama imatha kugawidwa muntchito yamanja ndikugulitsa. Pamafunika kuganizira mofatsa kuchokera pagawo ndi pb mastolout katundu, komanso katundu wa zomwe zimagwiritsidwa ntchito. Kuwala kwamanja ndikosavuta ndipo kumagwiritsidwa ntchito pokonzanso magawo ang'onoang'ono.

Makina otsogola

• Kukhudza Screen + PLC Control Unit, yosavuta komanso yodalirika.

• Kupanga kwa kunja kwa kunja, kapangidwe kake kwamkati, osati kokhako kokha komanso kosavuta.

• Splux sprax imapanga atomization yabwino ndi kumwa pang'ono.

• Turge Trect ndi chotchinga chotchinga kuteteza chosokoneza cha onomax flux mu malo otsogola, ndikuonetsetsa kuti ntchito yabwino.

• Kusasinthika kokhazikika kosinthika ndikosavuta kukonza; Kutenthetsa kuwongolera, kutentha kokhazikika, chopindika chopindika, kuthetsa zovuta za njira yotsogola.

• Ogulitsa amagwiritsa ntchito mphamvu zapamwamba, zosasinthika chitsulo chimatulutsa mphamvu zapamwamba.

Zopweteka zopangidwa ndi titanium onetsetsani kuti magetsi otsika komanso ozizira.

• Ili ndi ntchito ya chiyambi cha nthawi yoyambira komanso kutsekeka kwa makina onse.